Metal Miter Gears

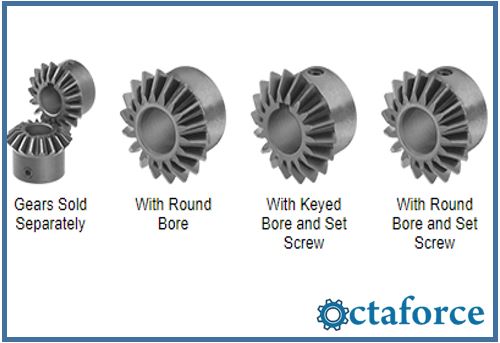

With straight, conically shaped teeth and a 1:1 speed ratio, miter gears connect two shafts at an angle without changing shaft speed or torque. They're more efficient than spiral miter gears because they create less friction.

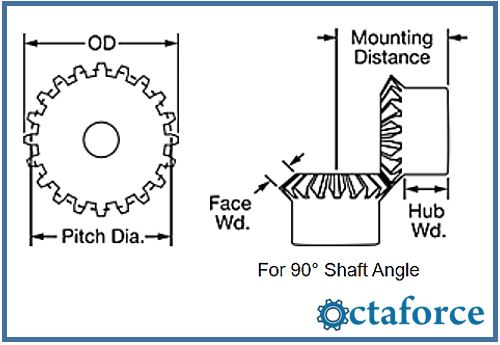

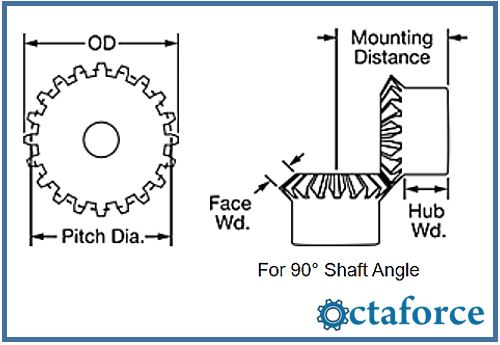

For two gears to mesh correctly, they must have the same pressure angle, shaft angle, pitch/module, and number of teeth.

Carbon steel gears have hard, strong, and wear-resistant teeth. They’re best for heavy duty and high-torque applications, such as lifting equipment. However, these gears will rust when exposed to moisture or corrosive chemicals. Some gears have hardened teeth for additional wear resistance; gears with teeth that are not hardened can be hardened to fit your application.

Stainless steel gears won’t rust in damp or wet environments. They’re commonly used in food-processing plants and other areas where frequent cleaning takes place.

Metal Miter Gears- Inch Gears

| Gear Pitch | Number of Teeth | For Shaft Angle | Pressure Angle | Gear Pitch Dia. | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Mounting Distance | Teeth Heat Treatment | Hub | Keyway | Set Screw Thread Size | ||

| Dia. | Wd. | Wd. | Dp. | ||||||||||||

| Round Bore- 1117 Carbon Steel | |||||||||||||||

| 48 | 18 | 90° | 20° | 3/8" | 0.4" | 0.08" | 0.286" | 1/8" | 0.406" | Not Hardened | 0.31" | 0.16" | - | - | - |

| 20 | 12 | 90° | 20° | 0.6" | 0.67" | 0.13" | 0.489" | 1/4" | 0.672" | Not Hardened | 0.5" | 0.31" | - | - | - |

| 16 | 12 | 90° | 20° | 3/4" | 0.84" | 0.16" | 0.583" | 5/16" | 0.812" | Not Hardened | 0.62" | 0.38" | - | - | - |

| Round Bore- 1144 Carbon Steel | |||||||||||||||

| 24 | 24 | 90° | 20° | 1" | 1.06" | 0.2" | 0.563" | 1/4" | 0.906" | Not Hardened | 0.625" | 0.281" | - | - | - |

| 20 | 20 | 90° | 20° | 1 | 1.07" | 0.23" | 0.813" | 3/8" | 1.125" | Not Hardened | 0.75" | 0.5" | - | - | - |

| 20 | 25 | 90° | 20° | 1-1/4" | 1.32" | 1/4" | 0.75" | 3/8" | 1.188" | Not Hardened | 1" | 0.375" | - | - | - |

| 16 | 16 | 90° | 20° | 1" | 1.09" | 0.22" | 0.75" | 3/8" | 1.063" | Not Hardened | 0.75" | 0.438" | - | - | - |

| 16 | 20 | 90° | 20° | 1-1/4" | 1.34" | 0.27" | 0.844" | 7.16" | 1.25" | Not Hardened | 1" | 0.5" | - | - | - |

| 16 | 24 | 90° | 20° | 1-1/2" | 1.59" | 0.31" | 0.875" | 1/2" | 1.375" | Not Hardened | 1" | 0.5" | - | - | - |

| 12 | 15 | 90° | 20° | 1-1/4" | 1.37" | 0.27" | 0.859" | 3/8" | 1.25" | Not Hardened | 1" | 0.5" | - | - | - |

| 12 | 15 | 90° | 20° | 1-1/4" | 1.37" | 0.27" | 0.859" | 1/2" | 1.25" | Not Hardened | 1" | 0.5" | - | - | - |

| 12 | 18 | 90° | 20° | 1-1/2" | 1.62" | 0.32" | 1.016" | 1/2" | 1.5" | Not Hardened | 1.25" | 0.625" | - | - | - |

| 12 | 18 | 90° | 20° | 1-1/2" | 1.62" | 0.32" | 1.016" | 5/8" | 1.5" | Not Hardened | 1.25" | 0.625" | - | - | - |

| 12 | 21 | 90° | 20° | 1-3/4" | 1.87" | 0.39" | 1.188" | 1/2" | 1.75" | Not Hardened | 1.375" | 0.688" | - | - | - |

| 12 | 21 | 90° | 20° | 1-3/4" | 1.87" | 0.39" | 1.188" | 5/8" | 1.75" | Not Hardened | 1.375" | 0.688" | - | - | - |

| 12 | 24 | 90° | 20° | 2" | 2.12" | 0.43" | 1.219" | 1/2" | 1.875" | Not Hardened | 1.5" | 0.688" | - | - | - |

| 12 | 30 | 90° | 20° | 2-1/2" | 2.62" | 0.54" | 1.484" | 5/8" | 2.313" | Not Hardened | 1.75" | 0.844" | - | - | - |

| 10 | 20 | 90° | 20° | 2" | 2.14" | 0.44" | 1.359" | 1/2" | 2" | Not Hardened | 1.625" | 0.813" | - | - | - |

| 10 | 20 | 90° | 20° | 2" | 2.14" | 0.44" | 1.359" | 5/8" | 2" | Not Hardened | 1.625" | 0.813" | - | - | - |

| 10 | 20 | 90° | 20° | 2" | 2.14" | 0.44" | 1.359" | 3/4" | 2" | Not Hardened | 1.625" | 0.813" | - | - | - |

| 10 | 25 | 90° | 20° | 2-1/2" | 2.64" | 0.55" | 1.625" | 3/4" | 2.438" | Not Hardened | 2" | 0.938" | - | - | - |

| 10 | 25 | 90° | 20° | 2-1/2" | 2.64" | 0.55" | 1.625" | 1" | 2.438" | Not Hardened | 2" | 0.938" | - | - | - |

| Keyway Bore with Set Screw- 1144 Carbon Steel | |||||||||||||||

| 16 | 16 | 90° | 20° | 1" | 1.09" | 0.22" | 0.75" | 3/8" | 1.063" | Hardened | 0.75" | 0.438" | 0.094" | 0.047" | 10-24 |

| 16 | 24 | 90° | 20° | 1-12/" | 1.59" | 0.31" | 0.875" | 1/2" | 1.375" | Hardened | 1" | 0.5" | 0.125" | 0.063" | 10-24 |

| 12 | 15 | 90° | 20° | 1-1/4" | 1.37" | 0.27" | 0.859" | 1/2" | 1.25" | Hardened | 1" | 0.5" | 0.125" | 0.063" | 10-24 |

| 12 | 18 | 90° | 20° | 1-12/" | 1.62" | 0.32" | 1.016" | 5/8" | 1.5" | Hardened | 1.25" | 0.625" | 0.188" | 0.094" | 1/4"-20 |

| 12 | 21 | 90° | 20° | 1-3/4" | 1.87" | 0.39" | 1.188" | 5/8" | 1.75" | Hardened | 1.375" | 0.688" | 0.188" | 0.094" | 1/4"-20 |

| 12 | 30 | 90° | 20° | 2-12/" | 2.62" | 0.54" | 1.484" | 5/8" | 2.313" | Hardened | 1.75" | 0.844" | 0.188" | 0.094" | 1/4"-20 |

| 10 | 20 | 90° | 20° | 2" | 2.14" | 0.44" | 1.359" | 1/2" | 2" | Hardened | 1.625" | 0.813" | 0.125" | 0.063" | 10-24 |

| 10 | 20 | 90° | 20° | 2" | 2.14" | 0.44" | 1.359" | 5/8" | 2" | Hardened | 1.625" | 0.813" | 0.188" | 0.094" | 1/4"-20 |

| 10 | 20 | 90° | 20° | 2" | 2.14" | 0.44" | 1.359" | 3/4" | 2" | Hardened | 1.625" | 0.813" | 0.188" | 0.094" | 1/4"-20 |

| 10 | 25 | 90° | 20° | 2-1/2" | 2.64" | 0.55" | 1.625" | 3/4" | 2.438" | Hardened | 2" | 0.938" | 0.188" | 0.094" | 1/4"-20 |

| 10 | 25 | 90° | 20° | 2-1/2" | 2.64" | 0.55" | 1.625" | 1" | 2.438" | Hardened | 2" | 0.938" | 0.25" | 0.125" | 5/16"-18 |

| 8 | 24 | 90° | 20° | 3" | 3.18" | 0.64" | 1.766" | 1" | 2.75" | Hardened | 2.5" | 1" | 0.25" | 0.125" | 5/16"-18 |

| 8 | 28 | 90° | 20° | 3-1/2" | 3.68" | 3/4" | 2.094" | 1" | 3.25" | Hardened | 2.5" | 1.25" | 0.25" | 0.125" | 5/16"-18 |

| 6 | 24 | 90° | 20° | 4" | 4.24" | 0.86" | 2.313" | 1-1/2" | 3.625" | Hardened | 3" | 1.313" | 0.375" | 0.188" | 3/8"-16 |

Metal Miter Gears- Metric Gears

| Module | Number of Teeth |

For Shaft Angle |

Pressure Angle |

Gear Pitch Dia., mm |

OD, mm |

Face Wd., mm |

Overall Wd., mm |

For Shaft Dia., mm |

Mounting Distance, mm |

Teeth Heat Treatment |

Hub | Keyway | Set Screw Thread Size |

||

| Dia., mm |

Wd., mm |

Wd., mm |

Dp., mm |

||||||||||||

| Round Bore—1045 Carbon Steel | |||||||||||||||

| 1.5 | 20 | 45° | 20° | 30 | 32.8 | 11 | 19.3 | 8 | 45 | Not Hardened | 25 | 7.8 | - | - | - |

| 1.5 | 20 | 60° | 20° | 30 | 32.6 | 9 | 22.3 | 8 | 40 | Not Hardened | 25 | 12.6 | - | - | - |

| 1.5 | 20 | 120° | 20° | 30 | 31.5 | 5 | 20.7 | 8 | 26 | Not Hardened | 26 | 13.9 | - | - | - |

| 2.5 | 20 | 45° | 20° | 50 | 54.6 | 18 | 31.9 | 12 | 75 | Not Hardened | 40 | 12.6 | - | - | - |

| Round Bore with Set Screw—1045 Carbon Steel | |||||||||||||||

| 1 | 20 | 90° | 20° | 20 | 21.4 | 5 | 14 | 8 | 20 | Hardened | 16 | 8 | - | - | M4 |

| 1 | 20 | 90° | 20° | 20 | 21.4 | 5 | 14 | 10 | 20 | Hardened | 16 | 8 | - | - | M4 |

| 1.5 | 20 | 90° | 20° | 30 | 32.1 | 8 | 21.1 | 10 | 30 | Hardened | 26 | 13 | - | - | M4 |

| Round Bore with Set Screw—303 Stainless Steel | |||||||||||||||

| 1 | 20 | 90° | 20° | 20 | 21.4 | 5 | 14 | 6 | 20 | Not Hardened | 16 | 8 | - | - | M4 |

| 1 | 25 | 90° | 20° | 25 | 26.4 | 6 | 15.2 | 6 | 23 | Not Hardened | 20 | 8 | - | - | M4 |

| 1.5 | 20 | 90° | 20° | 30 | 32.1 | 8 | 21.2 | 8 | 30 | Not Hardened | 26 | 13 | - | - | M4 |

| 1.5 | 25 | 90° | 20° | 38 | 39.6 | 9 | 22.3 | 10 | 34 | Not Hardened | 30 | 11.5 | - | - | M4 |

| Keyed Bore with Set Screw—1045 Carbon Steel | |||||||||||||||

| 1 | 30 | 90° | 20° | 30 | 31.4 | 6 | 17.7 | 12 | 28 | Hardened | 26 | 10 | 4 | 1.8 | M5 |

| 1.5 | 20 | 90° | 20° | 30 | 32.1 | 8 | 21.2 | 12 | 30 | Hardened | 26 | 13 | 4 | 1.8 | M5 |

| 1.5 | 30 | 90° | 20° | 45 | 47.1 | 10 | 28.2 | 15 | 43 | Hardened | 36 | 16 | 5 | 2.3 | M5 |

| 2 | 20 | 90° | 20° | 40 | 42.8 | 10 | 24.9 | 15 | 37 | Hardened | 34 | 14 | 5 | 2.3 | M5 |

| 2 | 25 | 90° | 20° | 50 | 52.8 | 12 | 24.3 | 15 | 40 | Hardened | 40 | 10 | 5 | 2.3 | M5 |

| 2 | 30 | 90° | 20° | 60 | 62.8 | 12 | 29.4 | 15 | 50 | Hardened | 45 | 12.5 | 5 | 2.3 | M5 |

| 2 | 30 | 90° | 20° | 60 | 62.8 | 12 | 29.4 | 20 | 50 | Hardened | 45 | 12.5 | 6 | 2.8 | M5 |

| Keyed Bore with Set Screw—303 Stainless Steel | |||||||||||||||

| 2 | 20 | 90° | 20° | 40 | 42.8 | 10 | 24.9 | 12 | 37 | Not Hardened | 34 | 14 | 4 | 1.8 | M4 |